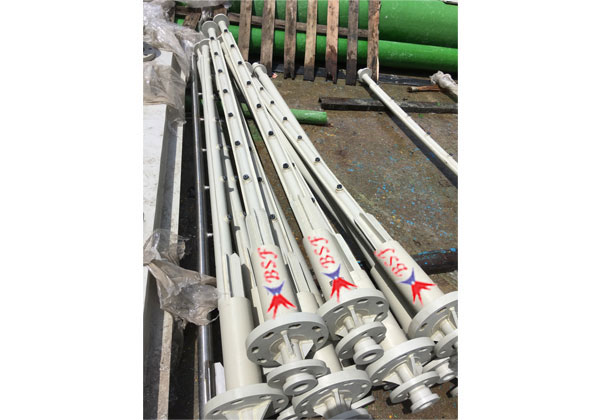

BS Projects is a leading FRP Headers manufacturer in India.

| Product Details : | |

|---|---|

| Header Material | FRP (Fibre-reinforced plastic) |

| Size | Customize |

| Country of Origin | Made in India |

GRP / FRP using Alpolite or Derakane 470-300 momentum resin, CPVC + GRP / FRP, ECTFE + GRP / FRP

Catholyte headers are the heart of the chloro alkali plant where the hydrogen comes in contact with NaOH

MOC : PPH 2222 + GRP / FRP using Dracaena 411-350 momentum resin

MOC : PPR + GRP / FRP using Dracaena 411-350 momentum resinmipl